Why does our yogurt cup filler be POPULAR?

What is a yogurt cup filler?

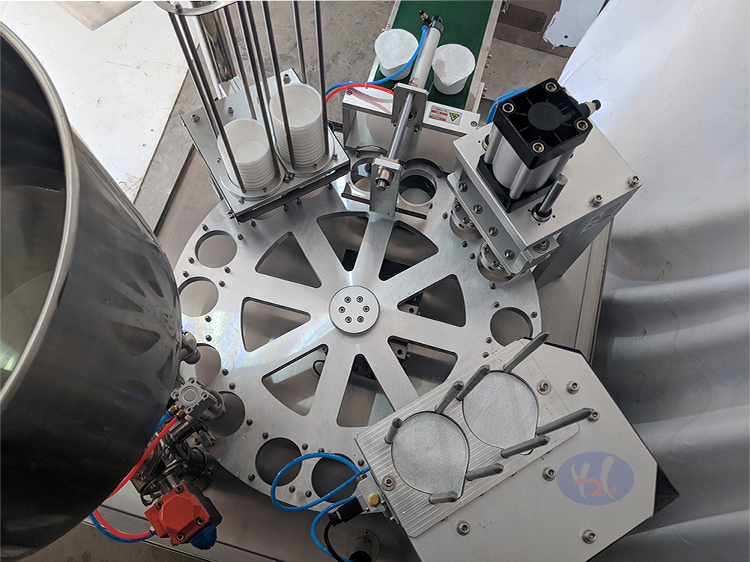

Our yogurt cup filler is engineered to precisely fill a diverse range of pasty materials-including yogurt, salad paste, porridge, pudding, and honey-into cup containers of various specifications. It also integrates cup sealing and date coding functions for the cup body in a single workflow. In the following section, we’ll break down the key features that make our yogurt packaging equipment a top choice for our customers worldwide.

What cup types is our yogurt cup filler compatible with?

The automatic turntable plastic cup filling and sealing machine works with a wide range of cup types, meeting all customers’ diverse production needs.

*Yogurt cups: Food-grade cups for filling, sealing and storing all yogurt types, compatible with automated filling machine for yogurt.

*Paste jars: Food-grade glass/plastic jars for packaging various thick pastes, adapted for paste filling and airtight sealing equipment.

*Pudding cups: Lightweight food-safe plastic cups for pudding, jelly and creamy gelatinous foods, ideal for high-speed automated filling and sealing.

*Porridge cups: Sturdy heat-resistant food-grade cups for ready-to-eat porridge/gruels, with leak-proof design for hygienic automated filling.

What functions does our yogurt packaging equipment offer?

Our best-selling yogurt cup filler features integrated filling, sealing, date coding, and optional UV disinfection. This all-in-one unit is engineered to meet customers’ yogurt packaging requirements seamlessly.

*Fill: Precisely dispenses pre-set volumes of yogurt, paste, pudding and other viscous materials into cups of various specifications with high accuracy and no spillage.

*Seal: Creates an airtight, leak-proof seal on cup openings to preserve product freshness and prevent contamination during storage and transportation.

*Date Print: Prints clear, durable production and expiry dates on cup bodies/surfaces for compliance with food safety labeling standards and traceability.

*UV disinfection: An optional sanitization step that uses UV light to disinfect cup interiors before filling, enhancing food hygiene and product safety.

What factors should customers consider when choosing a yogurt filling machine?

Whether you’re launching a new yogurt packaging line, upgrading existing equipment, or expanding your yogurt production business, several key factors need to be taken into account.

*Original factory: Opting for an original factory supplier ensures genuine, high-quality yogurt filling machines with reliable after-sales service, authentic spare parts and professional technical support.

*Capacity: Machine capacity should match your actual yogurt production output—choosing the right hourly filling volume avoids production bottlenecks or wasted operational costs.

*Packaging demands (Customization Service Available): Your specific yogurt packaging demands (e.g., cup size, material, packaging process) matter most, and a supplier with available customization service can tailor the machine to fit your unique production needs perfectly.

*Price: Consider the cost-performance ratio rather than just the single price—balance the machine’s price with its quality, functions and after-sales to ensure long-term operational value for your yogurt production business.

Conclusion

Our Rotary Yogurt Cup Filling And Sealing Machine is a market favorite for its great versatility, all-in-one functions and strong adaptability. It fits various viscous materials and cup types, with filling, sealing, date coding and optional UV disinfection. As an original factory, we provide customization, balanced capacity-price ratio and reliable after-sales—Customers’ ideal choice for efficient yogurt packaging production.