This YZH-300J-2 Roll film filling and sealing machine with code is an automatic filling and sealing machine, a more convenient operation, specially designed for hospitals, laboratories, beauty salons, small and medium-sized enterprises, and so on. It is very suitable for filling small measure liquid and paste.

Whatsapp:

+86 17838313979E-mail:

[email protected]The YZH-300J-2 automatic rotary yogurt cup filling and sealing machine is an efficient equipment used for large-scale production of yogurt products on production lines. The cup filling and sealing machine can automatically complete the filling and sealing of cups, greatly improving production efficiency and product quality. This article will introduce in detail the working principle, advantages, and applications of the automatic rotating yogurt cup filling and sealing machine.

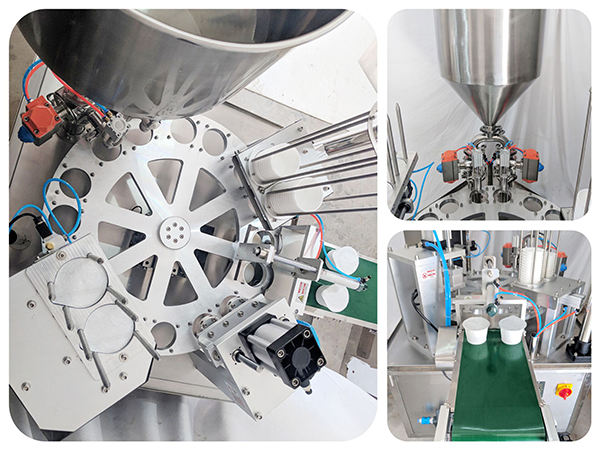

Fully automatic filling and sealing machine, through PLC controller and various pneumatic electronic accessories, realizes automatic cup dropping, ultraviolet sterilization (optional), automatic filling, automatic sealing, automatic coding (optional), automatic capping (optional) (matching), automatically sending finished products to the assembly line to achieve mass production.

Here is the yogurt cup filling and sealing machine on the YouTube video for your reference!!

This rotary cup filling and sealing machine uses advanced automation technology to realize automatic feeding, filling, sealing, and discharge of cups. During the work process, the yogurt cup will be automatically fed into the machine, and then the accurate amount of yogurt will be injected through the filling system. Then the cup will be sealed by the sealing system, and the final product will be discharged to the next production link. The entire process is completed automatically, which greatly reduces manual operations and improves production efficiency.

Thickened steel;

Efficient sealing;

Electric eye sensor;

Precise film cutting;

Mold customization;

Intelligent temperature control;

1. Using PLC and man-machine interface control, the operation is simple and clear;

2. Ribbon date printer, UV, hopper with heating and mixing protective cover optional, etc;

3. Featured with automatic load cup, filling, sealing, and output into one with a high degree of automation;

4. The filling accuracy is high, the electric eye automatically tracks and corrects the sealing position, and the sealing pattern is accurately aligned;

5. The YZH-300J-2 Roll film filling and sealing machine with code is made of high-quality 304 stainless steel and aluminum alloy, which meets GMP requirements;

| Model | YZH-300J-2 |

| Voltage | 110V/220V/380V |

| Power | 1.6KW |

| Air pressure | 0.5-0.7Mpa |

| Cup diameter | customized |

| Working speed | 1600-1800cups/h |

| Filling volume | According to the cup volume |

| Machine dimension | 130x160x170cm |

| Machine weight | 480kgs |

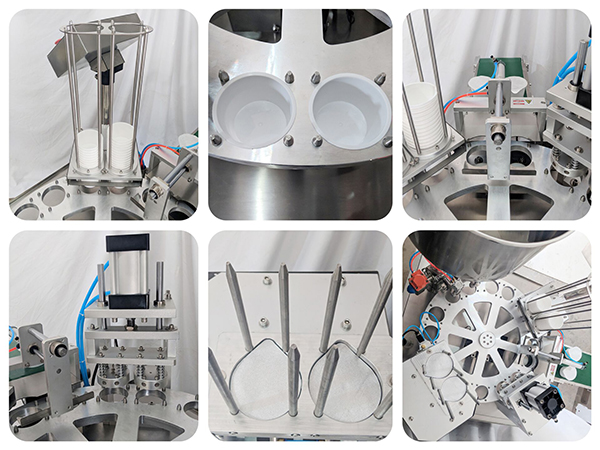

1. Automatic cup dropping

Put the cup into the cup drop holder, and the machine will automatically drop the box or cup into the alumina-resistant mold;

2. Aluminum acid-resistant mold

Ensure longer service life, no rust, safer and more hygienic;

3. Automatic filling

When the cup or box moves to the filling position, the machine senses the cup and automatically fills it, without the need for manual control of the switch. No cup, no filling

4. Automatic retracting and unfolding film

After filling, the cup or box moves to the film-placing position. The machine senses the cup and automatically places and closes the film;

5. Automatic sealing and film cutting

When the cup or box reaches the sealing point, the machine senses it and automatically seals and cuts the film;

6. Automatic cup dispensing

All processes have been completed, and the product has been finished and taken out of the machine automatically. It can also be used with the conveyor belt to directly discharge the cup to the conveyor belt and proceed directly to the next step;

Coding function

The roll film sealing cooperates with the coding machine to print the production date;

Coding function

Usually when sealing film, the production date needs to be printed, and an inkjet printer will be selected. The inkjet printer needs to be used with a conveyor belt;

Conveyor

With the conveyor belt, the cup can be directly discharged onto the conveyor belt, and directly enter the next step through the conveyor belt for packaging, etc.;

In general, the automatic rotary yogurt cup filling and sealing machine is a very important piece of equipment that can greatly improve the production efficiency and product quality of the yogurt production line. With the continuous advancement of food processing technology, it is believed that this kind of machine will be more widely used and developed in the future. If you are also interested in our yogurt-filling machine, please feel free to leave a message with us online!!

If you need our products please write down any questions, we will reply as soon as possible.