How To Use Tablets Pill Press Machine

What Is A Tablet Press Machine

The tablets/ pill press machine is mainly designed to manufacture tablets or pills. It is one of the most commonly used equipment in the pharmaceutical industry. It is a machine used to compress powdered or granular pharmaceutical ingredients into solid tablets. Tablet presses usually consist of several parts, including a feeding system, tablet pressing chamber, mold, pressure system, and control system.

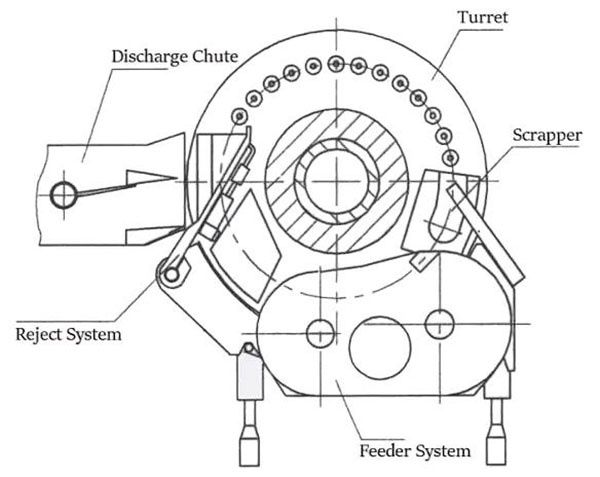

Rotary Tablet Press Machine Diagram

Working Principle Of Tablets Press Machine

In a tablet press, the pharmaceutical ingredients first enter the tableting chamber through the feeding system. In the tableting chamber, the pharmaceutical ingredients are compressed into the shape of solid tablets. A mold is a tool used to give tablets a specific shape and size, usually made of metal. The pressure system is used to provide sufficient pressure to ensure that the pharmaceutical ingredients can be fully compressed into tablets. The control system is used to monitor and adjust the entire tableting process to ensure that the quality of the tablets meets the requirements.

Tablet presses come in many different types and specifications, and the appropriate model can be selected according to different production needs. Generally speaking, tablet presses can be divided into two types: single punch and continuous. Single-shot tablet presses are suitable for small-batch production, while continuous tablet presses are suitable for large-scale production.

How To Use Pill Press Machine

First, you need to prepare the required raw materials, including drug powders, fillers, and lubricants. Ensure that these raw materials meet relevant pharmaceutical quality standards and are accurately weighed according to the formula. These raw materials are then mixed evenly to ensure the quality and stability of the tablets.

Next, you need to place the mixed raw materials into the feed port of the tablet press. Always clean and disinfect tablet presses before loading raw materials to prevent contamination from impurities. Then, adjust the parameters of the tablet press, including pressure, speed, temperature, etc., according to the equipment’s operating manual. Make sure these parameters meet the requirements of the tablet and make appropriate adjustments.

After adjusting the parameters, you can start the tablet press and observe the tablet production process. During the production process, be sure to regularly check the operating status of the equipment to ensure that everything is normal. If any abnormality is found, stop the machine immediately and conduct troubleshooting.

Finally, when the tablet press completes production, you need to clean and maintain the equipment promptly. Cleaning equipment can prevent impurity contamination and equipment damage, and maintain the normal operation of equipment. At the same time, regular maintenance of equipment is also very important to extend the service life of the equipment and ensure the quality of the tablets.

Tablet presses play a very important role in the pharmaceutical industry. It can help pharmaceutical companies improve production efficiency, reduce production costs, and improve tablet quality and stability. By using tablet presses, pharmaceutical companies can better meet market demand and improve their competitiveness. If you are also interested in tablet press machines, please feel free to leave a message with us online to get a free quotation and more detailed information on tablet press machines!!