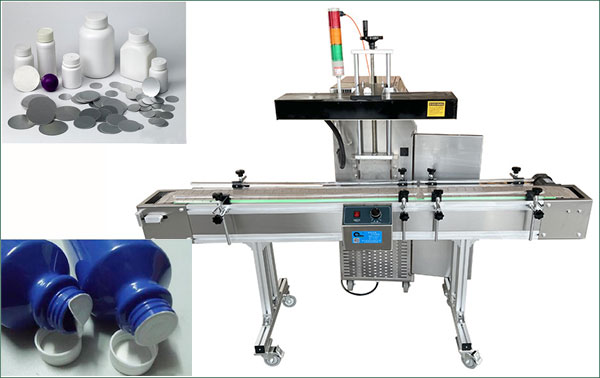

LGYS-3000 Water-cooled electromagnetic induction sealing machine electromagnetic induction sealing technology is an advanced and mainstream sealing method today. Induction sealing has no contact, fast sealing speed, and good sealing performance, which is suitable for sealing bottles made of non-metallic materials such as plastic and glass. It is widely used in pharmaceuticals, food, beverages, oil, daily chemicals, and other industries.

Whatsapp:

+86 17838313979E-mail:

[email protected]The automatic electromagnetic induction sealing machine with a water cooling system uses the principle of electromagnetic induction heating to achieve sealing. Through non-contact induction heating, the aluminum foil instantly melts the adhesive layer of the sealing film at high temperatures. After cooling, the sealing film adheres to the bottle mouth to complete the sealing. The water cooling system is an effective way to dissipate heat and can greatly improve the working efficiency and stability of the sealing machine. Compared with traditional sealing machines, water-cooled electromagnetic induction sealing machines are more efficient and have more stable performance.

First, let us take an In-depth understanding of the automatic electromagnetic induction sealing machine working principle. When the sealing machine is started, a high-frequency electromagnetic field will be formed on the sealing head. The aluminum foil material will generate an induced current under the action of the electromagnetic field, thereby generating heat to heat it and making it perfectly combine with the plastic bottle mouth. The water cooling system is used to reduce the temperature of the sealing head, thereby ensuring the long-term stable operation of the sealing machine.

Here is the electromagnetic Induction Sealing machine YouTube video working process in our factory for your reference!!

The design of the water cooling system mainly includes water coolers, water pumps, water pipes, and control systems. The water cooler is a device that cools hot water into cold water. The cold water is delivered to the sealing head through a circulating water pump, and then the hot water is discharged. The control system can monitor water temperature and pressure to ensure the stable operation of the water cooling system.

The water cooling system’s advantage is that it can quickly reduce the temperature of the sealing head and improve the working efficiency and stability of the sealing machine. Compared with the traditional air cooling system, the water cooling system has a better heat dissipation effect, can better protect the sealing head, and extend its service life.

Induction sealing is non-contact, with fast sealing speed and good product sealing. Suitable for sealing plastic, glass, and other non-metallic bottles. Widely used in pharmaceutical, food, beverage, oil, daily chemical, and other industries. Do not use this machine in flammable and explosive products and places.

1. Equipped with water cutoff, overcurrent, and overvoltage protection functions;

2. Stainless steel shell with chain plate conveyor, split structure, digital display, beautiful and elegant, easy to use;

3. Adopt a dual water-cooled self-circulation cooling system to cool the induction head and power tube respectively;

4. Non-contact heating, suitable for sealing plastic bottles, glass bottles various plastic hoses, etc., in line with GMP standards.

5. High sealing efficiency and easy operation. It has wide adaptability and is currently the most advanced technology for pharmaceuticals, food, beverages, health products, cosmetics, oils, and other chemical products.

1. High sealing efficiency and easy operation;

2. Non-contact heating, suitable for sealing plastic bottles, glass bottles, and various composite plastic hoses, and complies with GMP standards;

3. Wide adaptability, it is the current sealing technology for pharmaceuticals, food, beverages, health products, cosmetics, oils, and other chemical products;

Input power supply: AC220V±10%, 50Hz

Maximum power: 3KW

Sealing diameter: φ20~φ180mm (sealing mouth shall be adjusted)

Sealing height: 20 ~ 400mm

Sealing speed: 6 ~ 18m/min

Cooling method: Water cooling

Main engine weight: 108kg net weight and 137kg gross weight

Conveyor (optional) Weight: 60kg net weight, 85kg gross weight

Main machine size: 680×570×1400, packing 740×630×1620

Conveyor size: 1880×570×900, packing 1960×630×980

Conveyor belt load: 50kg

Production standard: Q/WCH 01-2007

Control Panel

Intelligent operation panel, key-type control, simple operation, easier to use;

Rotating sensor head

The rotating sensor head can adjust the sealing size to achieve a wide range of sealing;

Chain conveyor line

High load-bearing capacity, can carry multiple products, improving sealing efficiency;

Electric lift

The inlet size of the conveyor table can be adjusted to ensure that bottles of various diameters can be conveyed;

Vents

The design of heat dissipation holes on both sides of the machine allows the machine to dissipate heat quickly to maintain stable operation for a long time;

In general, the automatic electromagnetic induction sealing machine is an efficient and stable packaging equipment. The application of a water cooling system gives it a better heat dissipation effect, which can improve work efficiency and extend service life. With the continuous development of the packaging industry, it is believed that automatic electromagnetic induction sealing machines will be more widely used.

If you need our products please write down any questions, we will reply as soon as possible.