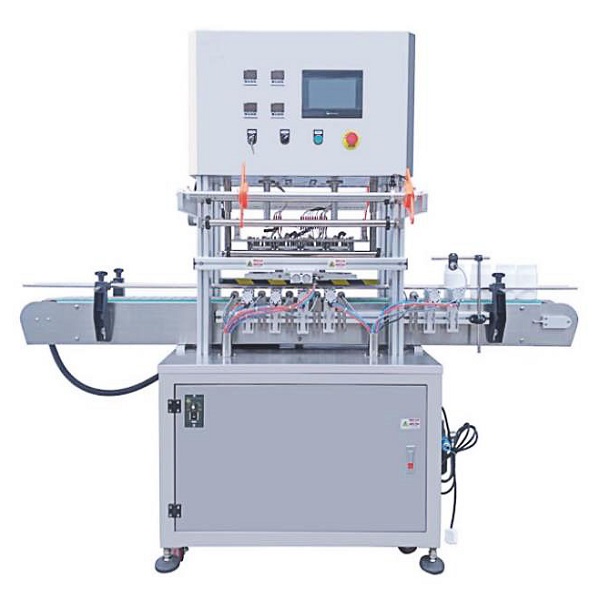

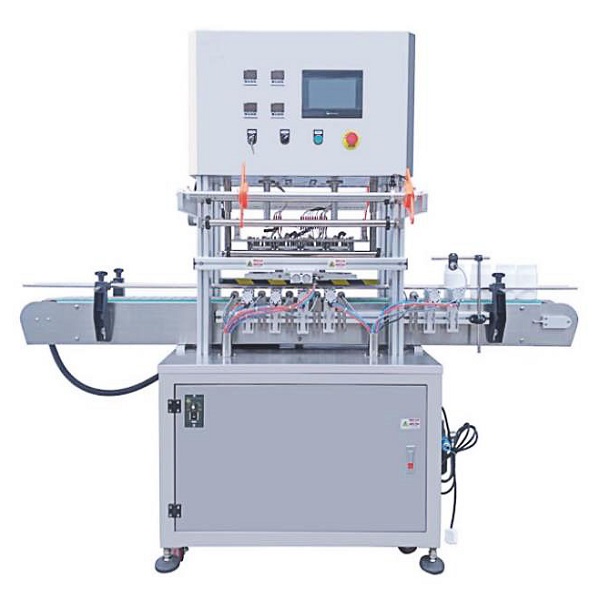

GCBS-750 Assembly line bottle barrel aluminum foil sealing machine is a new type of automatic sealing machine. It is mainly suitable for packing round, square plastic bottles or barrels, etc. It can seal 2,4 or 6 bottles at one time to improve production efficiency.

Whatsapp:

+86 17838313979E-mail:

[email protected]GCBS-750 Industrial automatic aluminum foil sealing machine for bottle and barrel is a device used to seal bottles and barrel containers. It can complete the sealing operation quickly and efficiently, improve production efficiency, and reduce labor costs. This automatic aluminum foil sealing machine is suitable for sealing films of various large-diameter plastic bottles in food, pharmaceutical, chemical, cosmetics, and other industries. It has the functions of being moisture-proof, leak-proof, extending product shelf life, and anti-theft and anti-counterfeiting.

The assembly line bottle and barrel aluminum foil sealing machine’s working principle is to seal the aluminum foil on the bottle or barrel mouth by heating and pressing to achieve a sealing effect. It usually consists of a conveying system, heating system, pressing system, and control system, each part plays an important role. This machine is an automatic plastic barrel sealing machine. It uses a heat sealing and cutting device, a worktable in and out movement device, and a film rewinding positioning device. It controls the heat sealing temperature and heat sealing time through the display screen, and the photoelectric sensor controls the position of the sealing film to achieve a perfect sealing effect.

The conveying system is responsible for delivering the bottles or barrels to be sealed to the designated location;

The heating system provides enough heat to heat the aluminum foil to a closing temperature;

The pressing system is responsible for pressing the heated aluminum foil to the mouth of the container to ensure the sealing effect;

The control system monitors and regulates the entire sealing process to ensure the stable operation of each link;

Here is the industrial automatic aluminum foil sealing machine YouTube video working process in our factory for your reference!!

| Model | GCBS-750(1T2) | GCBS-1500(1T4) |

| Voltage | 110v/220v/380v | 110v/220v/380v |

| Power | 1 KW | 1.6 KW |

| Working Pressure | 0.4-0.6 Mpa | 0.4-0.6 Mpa |

| Production Capacity | 750 pcs/h | 1500 pcs/h |

| Size | 200*100*175 cm | 200*120*175 cm |

| Weight | 300 kg | 380 kg

|

Its efficient, stable sealing effect and automated production process;

It can quickly complete large-volume sealing operations, greatly improving production efficiency and reducing labor costs;

Due to its automated characteristics, it also reduces the impact of human factors on sealing quality, ensuring the sealing and hygienic safety of the product;

1. Optional coding machine, timing film rolling, and other functions;

2. Automatic sealing, saving manpower and improving sealing quality;

3. Heat-sealing materials of different materials and thicknesses can be used;

4. Can be used with a variety of equipment, such as liquid filling machines, paste filling machines, etc.;

5. The whole machine is made of 304 stainless steel and aluminum alloy materials, and meets food GMP requirements;

6. Digital display LCD controls sealing temperature and sealing time, photoelectric sensor roll film position tracking, accurate pattern after sealing;

7. It is electrically driven and requires a gas source. It is suitable for small businesses, restaurants, hotels, shops, supermarkets, canteens and other business places;

In general, as efficient and stable sealing equipment, the liner aluminum foil sealing machine for bottles and barrels has important application value in the food, pharmaceutical, cosmetics, and other industries. As the degree of industrial automation continues to improve, its market demand will also continue to increase. However, when manufacturers select and use the liner aluminum foil sealing machine for bottles and barrels, they need to comprehensively consider its advantages and disadvantages, and make reasonable selections and configurations according to their own production needs. At the same time, manufacturers should also strengthen the maintenance and upkeep of equipment to ensure its long-term stable operation and provide reliable guarantees for production.

If you need our products please write down any questions, we will reply as soon as possible.